Metal Buildings 39 Steel Building Types & 125+ Kits

Table Of Content

This free, user-friendly tool provides comprehensive access to various features, allowing you to select doors, windows, and other structural elements while keeping track of the overall cost and budget. BuildingsGuide offers a full range of custom metal buildings throughout the USA and Canada. Our metal building kits include garages, workshops, metal homes, shop houses, and other steel buildings. For metal and steel building kit packages, there's no better partner than BuildingsGuide.

Design Guide 24: Hollow Structural Section Connections (Second Edition)

Metal Buildings design from Havit Steel provides an optimized solution for your project. We can provide you with the most efficient design and construction plan, which is fast and smooth to complete construction for your steel building projects. BS EN [19] specifies general requirements for the execution of structural steelwork as structures or as manufactured components, depending on the Execution Class of the structure.

Collcoll hides stairs and seats in pixellated wooden structure at Pricefx office

All frames experience second-order effects, typically because under lateral loads (or simply due to frame imperfections), the vertical loads are no longer concentric with the bases. The effect of this displacement is not accounted for in a first-order analysis. Some frames are sufficiently stiff such that second-order effects are small enough to be ignored. When second-order effects must be accounted for, this can be achieved by using second-order analysis, or by a simple amplifier of the lateral loads. For ease of construction, columns are usually erected in two, or sometimes three storey sections, i.e. approximately 8 m to 12 m in length.

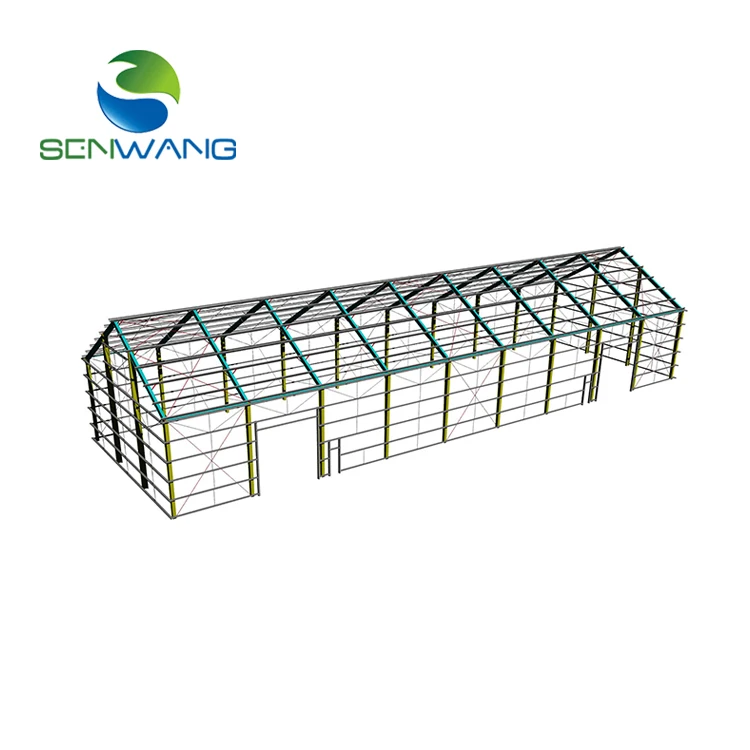

Agricultural Barn Metal Buildings

You don't ever need to trudge through another commercial rental building again. When your business needs a custom design to accommodate your goals, commercial metal buildings are the best investment you can make. In terms of building weight, steel structures are lighter in weight than concrete structures. The self-weight of steel structures is generally about two-thirds or one-half of that of steel-concrete systems. According to the above calculation rules, a lightweight steel structure building will significantly reduce and mitigate seismic forces, thereby protecting the stability of the entire building.

10 building projects win top steel engineering and architecture awards - Building Design + Construction

10 building projects win top steel engineering and architecture awards.

Posted: Thu, 05 May 2016 07:00:00 GMT [source]

Input your dimensions for building size

The amount of side paneling you elect to include will be a factor as well. You can go with a roof-only structure, a partially-enclosed structure, or a fully-enclosed building. The gauge of steel you choose for your framing and paneling will also help to decide final pricing. Your particular installation location could play a role in the price, as well. Whether you need space for business or personal use, a metal building will suit you. Easily insulate metal buildings and look forward to an energy-efficient utility building!

Policy support needed to boost steel structure building industry - The Business Standard

Policy support needed to boost steel structure building industry.

Posted: Wed, 09 Aug 2023 04:59:03 GMT [source]

Column sections are joined with splices , typically 300 mm to 600 mm above the floor level. For buildings up to eight storeys high, braced steel frames are commonly used with bracing members generally located within a cavity in the facade, or around stairs or other serviced zones. Gas metal arc (GMAW) or metal inert gas (MIG) welding processes use a continuous filler metal electrode supplied by solid wire on a reel. Advantages are high versatility, unlimited electrode length, welding in all positions, slag-free weld bead, and high deposition rates. The size, thickness, and position of the weld are important criteria for selection of the specific welding process.

Build your Metal Building with CA Metal Building kits

It is then important to ensure that the physical details correspond to the design assumptions. Integration of services and structure reduces the construction depth but requires a perforated structure; installation and subsequent refitting of services may be more difficult. Welding processes differ by base metals, method of shielding, filler metal type and form of input, heat input, and feasible deposition rate (pounds of filler metal per hour).

Pre Engineered Metal Buildings Construction Company

The detailer prepares shop drawings using design drawings, standard details for connections, and, importantly, has knowledge of operations for fabrication and erection. Pacific Metal Buildings has them, and we offer the best metal building prices. We’re able to provide you with custom metal buildings to meet any need. We offer metal carports, metal garages, metal barns, commercial metal buildings, clear span metal buildings, and more.

Engineered Steel Structure

Weld metal is strengthened by solidification grain structure, solid solution strengthening by alloying additions, transformation hardening by different cooling rates, or precipitation hardening by aging heat treatment. The covering for “stick” electrodes in certain arc welding processes, under the heat of the arc, generates a gaseous shield. Other welding processes use a shielding gas supplied to the point of welding.

Potential problems with fit-up of structural steel include inability to align bolt holes and obstructions from either the configuration of the individual member, adjacent members, or work by other trades. Standard practice allows reaming bolt holes a specified amount to allow fit-up. Today's explosive growth in the tonnage of goods moved by trucks is transforming transportation terminals into major construction opportunities.

In all cases, the additional fabrication costs make trusses more expensive than conventional beam and column structures. Long spans result in flexible, column-free internal spaces, reduced substructure costs, and reduced erection times. This broad range of benefits means that they are commonly used in a wide range of building types.

Common ones include structural self-weight, floor live load, roof live load, roof area dust load, vehicle load, crane load, equipment dynamic load, and Wind, snow, ice, waves, and other natural loads. Simple connections are nominally pinned connections that transmit end shear only and do not transfer significant moments. For buildings up to four storeys high, continuous frames may be used in which the multiple beam to column connections provide bending resistance and stiffness to resist horizontal loads. This is generally only possible where the beams are relatively deep (400 mm to 500 mm) and where the column size is increased to resist the applied moments.

Composite construction is the dominant form of construction for the multi-storey building sector. Its success is due to the strength and stiffness that can be achieved, with minimum use of materials, utilising the compressive strength of concrete and the tensile strength of steel. Composite floors offer significant advantages related to speed of construction and reduced overall construction depth. The over-arching requirement for design in the UK is to satisfy the Building Regulations.

If you’re beginning a business in any of these industries, you want a metal building. Custom designs can accommodate whatever access, storage, height, or ventilation your enterprise needs! Even better, metal buildings are fire-resistant and pest-resistant, so you know that you, your employees, and your investment are secure in a steel structure. The length of the member is also an essential factor affecting the stability coefficient. According to Euler’s formula, the stability coefficient is high when the member length is small. Still, the stability coefficient will decrease sharply when the member length increases to a certain extent.

We recommend calling your local building inspector for a list of regulations. You may also want a soil engineer to assess your property and give advice on a location and preferable foundation. Before your building arrives, the foundation must be installed, and the area must be completely cleared of all vegetation and/or debris. Almonds, artichokes, figs, and pomegranates are all primarily produced in this state. California has only 80,000 farms and ranches, which is less than 4% of the nation’s total, yet it produces 13% of the nation’s agricultural value. Large metal buildings are an essential part of this, and other, industries.

In addition to the main frame structure calculations, we also need to pay attention to the details of the steel structure, such as the bending capacity of the connection points and the eccentricity of the rods. With common spans of 20 to 60 feet, the lean-to frame is attached to and is supported by a larger rigid frame. The lean-to is much different from the single slope, in that it is supported on the high side by an adjoining building column. It is recommended that a minimum of 1’-3” roof step be in place to add on a lean-to but is a very economical solution for expansions of existing buildings.

Comments

Post a Comment